Our Group has the manufacturing facilities, the technical know-how, and the depth of experience to supply Slide Bearing for all International Brands of equipments such as Steam Turbines, Motors, Compressors, Pumps and Blowers.

We offer bearing manufacturing services to industries like Power Plant (Steam & Hydro), refining, processing, petrochemical, chemical, pulp and paper, primary metals and other general industries. We have continuously updated both our physical plant and our manufacturing equipment to maintain a constant state-of-the-art position. Our goal is to supply products of the highest quality at the lowest possible cost.

Our Bearings are inter-changeable to the main equipment since these are manufactured using the similar quality standards and adopting the same technological processes used by the original manufacturers.

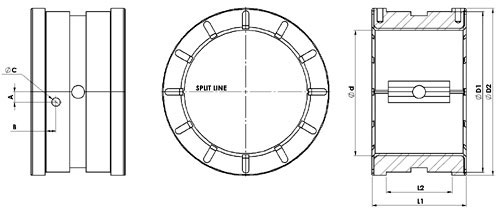

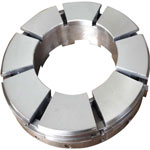

We have the most extensive range of Turbine Bearings in the industry, with designs from less than two inch (50 mm) to over 40 inches (1000 mm) in diameter, available in a wide variety of configurations. Combination thrust / journal bearing designs are also available for applications with limited axial space.

Our Turbine Bearings are designed to transfer radial loads from rotating shafts with minimum power loss and optimum dynamic characteristics. Our Engineers work collaboratively with customers to understand the performance expectations and operating conditions of the bearing and then provide a high-performing solution, manufactured to the highest quality standards in the industry.

We are able to work on any reverse engineered bearing project. We can reverse engineer a bearing from a sample, or work from your drawing and specifications. Our ability to quickly reverse engineer parts provides our customers with a flexible alternative when repairing their equipment. Perhaps your unit has undergone customized modification such as a turned journal or oversized housing. No problem, we can cost-efficiently reverse engineer a custom solution for you. Our experience in reverse engineering bearing include applications like cement plants, marine uses for ships and tug boats, dredging equipment, sugar mills, power generation facilities, and for various other uses.

Centrifugal pumps use an impeller to control the pressure and flow of fluids through a piping system. A bearing failure in a centrifugal pump can lead to catastrophic consequences, causing a hazardous work environment and expensive repairs to damaged equipment. Centrifugal pumps are a critical part of the manufacturing process in nearly every industry. Our expert bearing engineers produce the highest quality bearings, ensuring smooth and efficient operation of your centrifugal pumps.

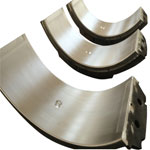

Besides OEMs, our group has also been catering to the needs of a large number of integrated plants in Steel, Cement, Process industry and Power Sector. Offering three different outer shell materials, bronze, steel, or cast iron, we produce a large assortment of babbitt bearings and seal types such as journal, elliptical, self-equalizing and tilting shoe.

Our product range also covers Guide Bearings for Hydro Turbines, Thrust Pads for Hydro generators & Bi-Metal Bearings for steam turbines.

When dealing with foreign-made units, finding parts can be impossible and overseas parts orders can take months. Simply send us the part and we will quickly put our experienced team to work and make a drawing with which your Bearing can be manufactured. Contact us today to learn how we can help you reverse engineer a Bearing.

We also provide quality bearing reconditioning services. The repair and reconditioning of your Slide bearings can not only save you economically but also save you the time when compared with buying a new Bearing. Our inventory is simply the final expression of our ingrained dedication to our philosophy of service to our customers.

Turbine parts run in very demanding conditions and you want the best job possible when using these units. When it comes to reconditioned turbine bearings, in most cases all components can easily be re-worked at a huge cost and time savings when compared with buying a new part. Thrust plates, thrust pads, radial pads and regular turbine bearings can be economically re-conditioned to provide our customers a quality part.

Our custom-engineered bearings increase the reliability and efficiency of gas, steam, and hydro turbines, compressors, gearboxes, motors and pumping systems.

Our expert engineering and refinement are reflected by our highly specialized Slide bearings – allowing us to deliver superior solutions for the most challenging applications.

61/32, T.T.K. ROAD, ALWARPET, CHENNAI – 600 018, TAMILNADU, INDIA. Phone: +91 44 4210 9594

Fax: +91 44 2498 5988