The company is professionally managed and is self sufficient having well Equipped Laboratory & work Shop with all modern machines of good make.

We also undertake Ultrasound test, Dye Penetration Test & other Non Destructive Tests. We also perform destructive tests like Bond test etc. The bearings are heated for the dehydrogenation before tinning / babbitting operation.

All products and components are subjected to chemical, physical and non-destructive tests. Some of these are UT tests for bond adhesion, DP tests for solidity of lining and MPI tests for shell soundness.

Any special tests such as hydro tests, residual stress tests and radiographic tests specific to a product can be carried out with external assistance. Facility for third party inspection is available.

We also offer machined compressor bearings for the oil industry to marine, babbitted seals and bushings for the marine industry.

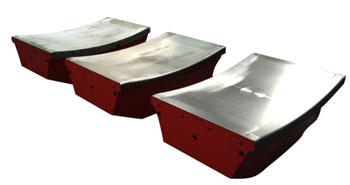

Capable of being applied to a wide variety of machinery, from compressors to, steam turbines, Blowers, Pumps, Ball Mills, and Motors , our Babbitt bearings meet high industry standards, but not limited to, ANSI, AS, MIL, and meet strict OEM specifications.

Produced by the CNC machining equipment and possessing +.001/-.000 inch precision tolerance, our turbine bearings are designed and manufactured according to client drawings and specifications.

61/32, T.T.K. ROAD, ALWARPET, CHENNAI – 600 018, TAMILNADU, INDIA. Phone: +91 44 4210 9594

Fax: +91 44 2498 5988